If you were to tell a stranger that foam has density, weight, and firmness characteristics, he or she would likely understand, given how common the terms are. However, one of the most confusing things about foam is the relationship between these characteristics. On the surface, it would seem the density or weight of a material would allow you to draw a correlation about its firmness, and vice versa. In general, this is often true, but when applied to foam products, density and firmness are independent values for determining a foam’s qualities.

It would be accurate to say density is a foam characteristic that is “over-applied,” rather than one that is misunderstood. The density of foam means the same thing as any other application of the term; the quantity or mass of a material per a measurable size or volume. This pertains to all varieties of foam, including expanded polystyrene (EPS), polyethylene, polyurethane foam, and others. How density is measured varies across materials though, and in the case of foam, density is found by weighing a 12″ x 12″ x 12″ block of the material. If a product has a 3LB density, that means its 12″ x 12″ x 12″ block weighed 3LB. And while it’s vital to understand that density does not pertain to the firmness of a foam product, it does correlate to the quality and longevity of a product.

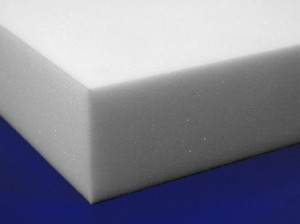

Many conventional foams have a density between 1LB and 3LB. However, the densest materials can be as much as 10 or 15LB. High-density foam, Like The Foam Factory’s 2.8LB density HD36-HQ foam, is optimal for uses that receive heavy or daily use like couch cushions, bedding, or automobile seating. Lower density foam is excellent for occasional-use products like shipping foam, crafts, or guest room mattress toppers.

Density is also sometimes referred to as weight, which is a more literal translation of the characteristic given the testing process. But because of this, it’s always important to specify whether you want to know a product’s overall weight, or its density weight. Consider a 6-inch thick, conventional foam queen mattress with a 2.8LB density. The material weight is correctly stated as 2.8LB, since that’s its density. However, the overall weight of the mattress would be about 46LB. That’s about 43LB worth of reasons to make sure you clarify which value you need to know, since both can be technically correct.

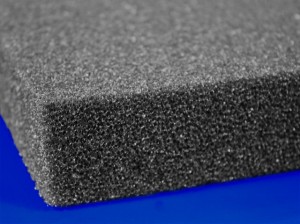

Firmness meanwhile, interprets the feel of foam and how it yields to weight and pressure. Its measurement is called Indentation Load Deflection (ILD) (also known as Indentation Force Deflection/IFD), found by mechanical performance testing. A foam sample measuring 15″ by 15″ by 4″ is used and the force in pounds that it takes a 50 square inch circular indenter to compress the material 1″ (25 percent of its thickness) is recorded. If the sample requires 36LB of pressure to indent it 1″, its ILD is 36. It is also important that the test material meets the standardized dimensions, as different thicknesses of the same material can support weight differently. A hard foam material will require greater force to reach 25 percent compression, and a softer material will require less. Most common materials have ILD values from 8 to 70, with some materials as high as 120 to 150. A low ILD example would be The Foam Factory’s 12ILD Super Soft Foam, while their Rebond Foam is very firm at 70ILD.

Firmness testing is done to help illustrate how a material will bear weight in end-use applications. It is important to interpret firmness values as an explanation of a material’s physical feel rather than its quality, which is reflected by its density. Because of the numerous structural and chemical makeups of foam, some foam sheets with higher densities can even have a lower ILD than foams with lower densities. For this reason, the two values should be looked at independently and used to help find a product that matches your preferences.

Understanding what these characteristics do and do not tell you about a foam material is very important for selecting the perfect product for an application. By understanding the values of these measurements, you can have a better idea of what to expect from a product and make a more educated purchase.